Applications

For large and small data centers, hospitals, water treatment plants and mission critical facilities.

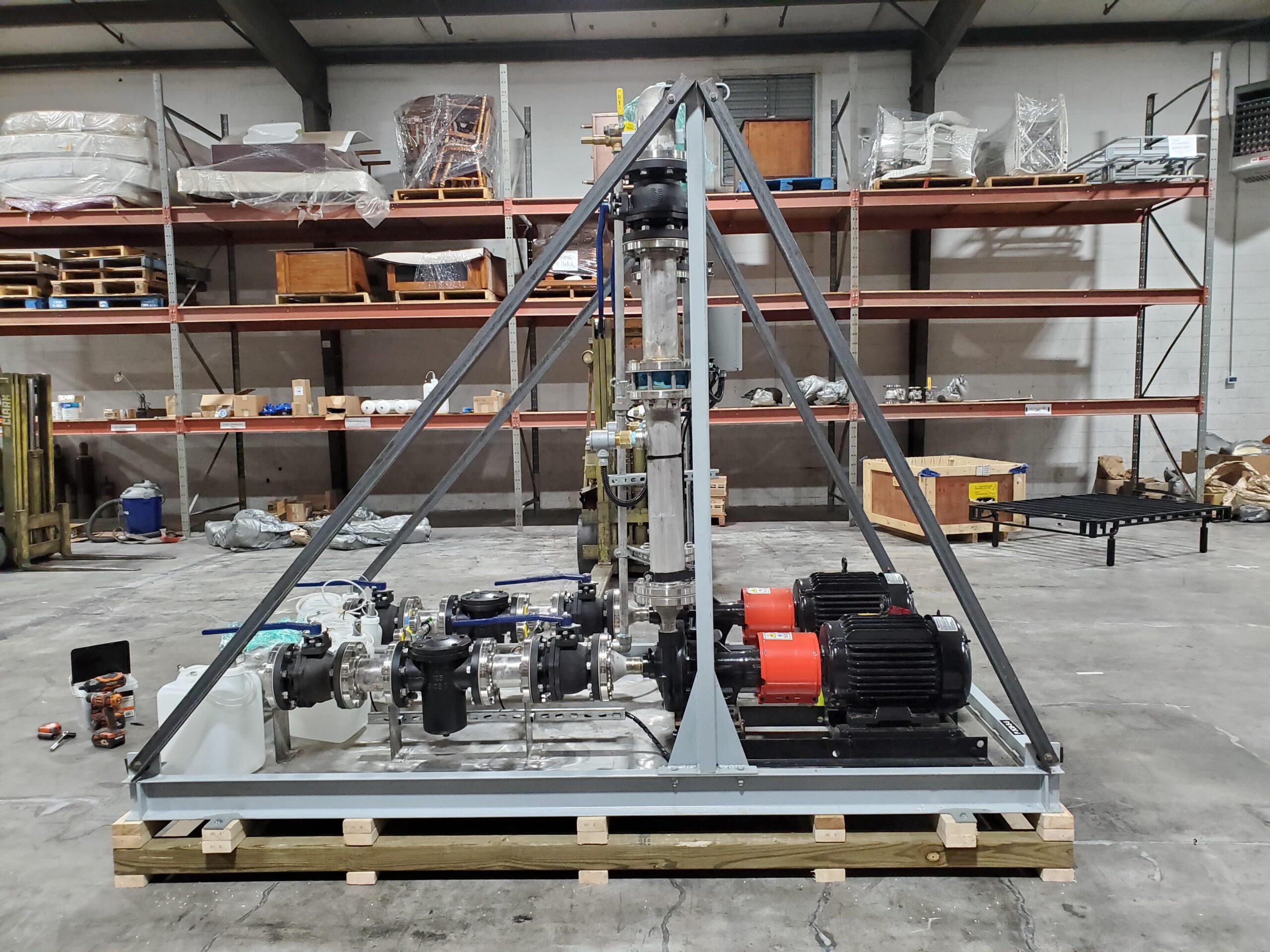

Fuel Polishing/Filtration Systems

Fuel Polishing Systems for Modern Diesel Engines

Advanced Machine Technologies, Inc. is a manufacturer of high-end automated systems with extensive experience in automated fuel oil systems. When fuel quality management is critical, AMT answers the call with the best fuel polishing technology on the market today for modern high pressure common rail engines.

New fuel from the pipeline typically does not meet engine fuel specifications. AMT’s proprietary fuel polishing technology is state-of-the-art and produces results comparable with the aircraft industry. Emergency system down time is not an option. Diesel fuel that does not meet the OEM specification is a sure way to incur downtime in the modern high pressure common rail engines. Additionally, this is an expense the owner will not carry. The Engine OEM will often deny warranty.

Don’t get caught wondering why your critical fuel system failed you when you needed it the most. Monitor your fuel with AMT’s online analysis, and state-of-the-art diesel fuel polishing reporting software. AMT systems are backed by Parker’s CleanDiesel™ Technology, one of the largest fuel laboratories in the world.

Fuel Polisher System Features/ Options Matrix

| A904V62H14 | A503V62H14 | A302V61V65 | A102V61V65 | A52V61V65 | |

|---|---|---|---|---|---|

| Flow Rate (GPM) | 90 GPM | 50 GPM | 30 GPM | 10 GPM | 5 GPM |

| ISO Reduction (ISO 4406) per pass | 2 Iso | 2 Iso | 2 Iso | 2 Iso | 2 Iso |

| PUMP Style | Gear | Gear | Gear | Gear | Gear |

| Horse Power | 10 HP | 10 HP | 2 HP | 2 HP | 2 HP |

| Voltage (typical) | 480 VAC 3 Phase | 480 VAC 3 Phase | 480 VAC 3 Phase | 480 VAC 3 Phase | 120 VAC 1 Phase |

| Recommended Filterd volume | up to 300k gallons | up to 100k gallons | up to 60k gallons | up to 30k gallons | up to 10k gallons |

| Filtration Stages | 2 stage | 2 stage | 2 stage | 2 stage | 2 stage |

| Water Seperation (Coalesing) | yes | yes | yes | yes | yes |

| BMS Connectivity | Recommended | Recommended | Recommended | Recommended | Recommended |

| Line Size | 3 in 150# flange | 2 in 150# flange | 1.5 in 150# flange | 1 in 150# flange | 0.75 in 150# flange |

| Approximate Footprint | 50" W x 80" D x 76"T* | 50" W x 80" D x 76"T* | 60" W x 20" D x 68" T | 60" W x 20" D x 68" T | 60" W x 20" D x 68" T |

AMT’s Fuel Polishing Systems Features Include:

- Operational Media Pressure 25 Psi (vs. competitors’ 15 Psi) Media Yields Substantially Longer Times Between Change-outs.

- Modbus BMS Connectivity Capability

- Onboard Leak Detection

- Ethernet Connectivity

- Variable Speed Pump for Improved Emergency Recovery

- Minimum 2-4 ISO 4406 Codes Per Pass

- Ultra High Efficiency Water Coalescor/Separator system. Meets or Exceeds Engine Manufacturers’ Requirements for Water Removal

Remote Fill Stations

High Pressure, High Volume

Offload Filtration

Pump Skids